|

本站僅提供期刊文獻檢索。 本站僅提供期刊文獻檢索。

【月旦知識庫】是否收錄該篇全文,敬請【登入】查詢為準。

最新【購點活動】 最新【購點活動】

|

| 篇名 |

AA-NC Semi-IPNs木器塗料--製備程序對塗料與塗膜性質之影響

|

| 並列篇名 |

AA-NC Semi-IPNs Wood Coatings—Effects of Manufacturing Processes on the Properties of Coatings and Films |

| 作者 |

盧崑宗 (Kun-Tsung Lu)、劉正字、林士棉 |

| 中文摘要 |

本研究係以三種油長之大豆油油變性醇酸樹脂(Alkyd)(短、中及長油型)、分別與胺基樹脂包括油溶性之三聚氰胺樹脂(M F)與尿素樹脂(U F)、對甲苯磺酸等, 依MF/UF/Alkyd=7.5/22.5/70(重量比),對甲苯磺酸催化劑之添加量為胺基樹脂重量之10%,作為酸硬化胺基醇酸樹脂(AA)之原料,再分別以2種連續式(A 法與B 法)及1種同步式(C 法)聚合反應之製備程序,與硝化纖維素(NC)依AA/NC=25/70(重量比)摻合而成AA-NC 半互穿聚合體網狀結構物(Semi-IPNs)作為木器塗料,探討製備程序對含不同油長醇酸樹脂之塗料與塗膜性質之影響。試驗結果發現,以中油型醇酸樹脂與胺基樹脂混合後,再加入對甲苯磺酸,先反應形成AA 樹脂後,再摻合NC(B 法)所製備之AA-NC semi-IPNs,其塗料性質能配合塗裝作業流程,而各種塗膜性質也最為均衡,適用為木器塗料。

The AA-NC semi-interpenetrating polymer networks (semi-IPNs) made from acid-curing amino-alkyd resin (AA) and nitrocellulose (NC) under AA/NC=25/75 (by wt.) were prepared by two kinds of sequential (method A, B) and one kind of simultaneous (method C) polymerization respectively for wood coatings. The AA was formulated by the composition of melamine-formaldehyde resin(MF)/ urea-formaldehyde resin(UF)/ soybean oil modified alkyd resin(Alkyd)=7.5/22.5/70(by wt.) and 10% of p-toluenesulfonic acid as catalyst was added based on the weight of amino resin. To explore and better understand the application of AA-NC semi-IPNs as wood coatings, the method A, B, and C manufacturing processes and three different oil length alkyd resins (short-oil, medium-oil, and long-oil modified alkyd) as the constituent of semi-IPNs respectively, were examined in this study. The results showed that the AA-NC semi-IPNs containing medium oil modified alkyd resin and by the manufacturing process of method B i.e MF+UF → Alkyd → p-toluenesulfonic acid → NC sequence had the balanced effect on properties of coatings and films and could readily be used for wood coatings. |

| 英文摘要 |

The AA-NC semi-interpenetrating polymer networks (semi-IPNs) made from acid-curing amino-alkyd resin (AA) and nitrocellulose (NC) under AA/NC=25/75 (by wt.) were prepared by two kinds of sequential (method A, B) and one kind of simultaneous (method C) polymerization respectively for wood coatings. The AA was formulated by the composition of melamine-formaldehyde resin(MF)/ urea-formaldehyde resin(UF)/ soybean oil modified alkyd resin(Alkyd)=7.5/22.5/70(by wt.)and 10% of p-toluenesulfonic acid as catalyst was added based on the weight of amino resin. To explore and better understand the application of AA-NC semi-IPNs as wood coatings, the method A, B, and C manufacturing processes and three different oil length alkyd resins (short-oil, medium-oil, and long-oil modified alkyd) as the constituent of semi-IPNs respectively, were examined in this study. The results showed that the AA-NC semi-IPNs containing medium oil modified alkyd resin and by the manufacturing process of method B i.e MF+UF → Alkyd → p-toluenesulfonic acid → NC sequence had the balanced effect on properties of coatings and films and could readily be used for wood coatings. |

| 起訖頁 |

1-12 |

| 刊名 |

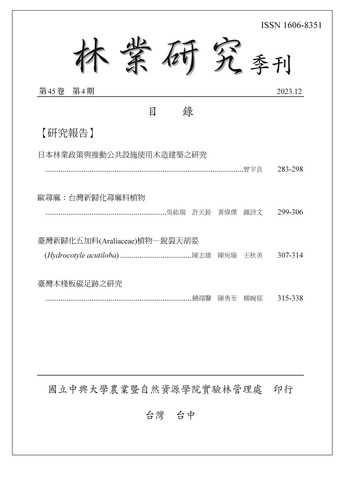

林業研究季刊 |

| 期數 |

200406 (26:2期) |

| 出版單位 |

國立中興大學農業暨自然資源學院實驗林管理處

|

| 該期刊-下一篇 |

台灣產海茄苳開花物候與授粉生態之研究 |

| |

|

新書閱讀

最新影音

優惠活動

|