|

本站僅提供期刊文獻檢索。 本站僅提供期刊文獻檢索。

【月旦知識庫】是否收錄該篇全文,敬請【登入】查詢為準。

最新【購點活動】 最新【購點活動】

|

| 篇名 |

多元醇液化柳杉為基質PU樹脂之薄膜性質及填縫膠合性能

|

| 並列篇名 |

Properties of Films and Performances of Gap-filling Adhesion of Polyurethane Resins Made from Polyhydric Alcohol Liquefied Cryptomeria Japonica |

| 作者 |

高毓斌、李文昭 |

| 中文摘要 |

本研究將多元醇液化柳杉與Desmodur L及Desmodur N兩種異氰酸酯在不同NCO/(OH+COOH)官能基莫耳比條件下混合調配聚胺基甲酸酯樹脂(Polyurethane resins;PU resins),分析其所製作PU樹脂薄膜之物理、機械性質及熱性質,並探討此PU樹脂應用於木材填縫膠合之可行性。由試驗結果得知,以Desmodur N為原料者之薄膜有較佳耐溶劑性及較大的拉伸變形量,以Desmodur L為原料者則有較大之彈性係數。DSC分析顯示常溫硬化之PU樹脂在熱掃描過程均出現放熱現象,其中以Desmodur L為原料者放熱現象較明顯,其放熱峰高度及溫度範圍均較大;TGA分析顯示以Desmodur N為原料者有較佳之耐熱性,其熱裂解重量損失主要發生在300-400℃,而以Desmodur L為原料者則發生在200-350℃,然不同NCO/(OH+COOH)莫耳比PU樹脂均呈現相似之熱裂解現象。將PU樹脂應用於填縫膠合時,以Desmodur L為原料且採用NCO/(OH+COOH)莫耳比1.5者具有最佳之溫水浸水及反覆煮沸浸水膠合強度。

In this study, polyhydric alcohol liquefied Cryptomeria japonica was blended with different isocyanate (i.e. Desmodur L and Desmodur N) with various NCO/(OH+COOH) molar ratios to prepare polyurethane resins. The physical, mechanical and thermal properties of PU films were analyzed and the feasibility of gap-filling adhesion of these PU resins was also investigated. The results show that films made with Desmodur N had the better solvent-resistance and had a larger tensile deformation. However, films that using Desmodur L as the raw material a higher elastic modulus. DSC analysis shows that room temperature cured PU resins appeared an exothermic phenomenon during the period of heat-scanning. While, using Desmodur L as the raw material had an exothermic peak with larger height and broader temperature range. TGA analysis shows that using Desmodur N as the raw material had a better heat-resistance; their weight loss due to thermo-degradation mainly occurred at 300-400℃, but it occurred at 200-350℃ for those using Desmodur L as the raw material. However, the PU resins with various molar ratios of NCO/ (OH+COOH) had similar thermal degradation behavior. When PU resins were used for gap-filling adhesion, using Desmodur L as the raw material with the NCO/ (OH+COOH) molar ratio of 1.5 had the best bonding strength after warm water and repetitive boiling water soaked. |

| 英文摘要 |

In this study, polyhydric alcohol liquefied Cryptomeria japonica was blended with different isocyanate (i.e. Desmodur L and Desmodur N) with various NCO/(OH+COOH) molar ratios to prepare polyurethane resins. The physical, mechanical and thermal properties of PU films were analyzed and the feasibility of gap-filling adhesion of these PU resins was also investigated. The results show that films made with Desmodur N had the better solvent-resistance and had a larger tensile deformation. However, films that using Desmodur L as the raw material a higher elastic modulus. DSC analysis shows that room temperature cured PU resins appeared an exothermic phenomenon during the period of heat-scanning. While, using Desmodur L as the raw material had an exothermic peak with larger height and broader temperature range. TGA analysis shows that using Desmodur N as the raw material had a better heat-resistance; their weight loss due to thermo-degradation mainly occurred at 300-400℃, but it occurred at 200-350℃ for those using Desmodur L as the raw material. However, the PU resins with various molar ratios of NCO/ (OH+COOH) had similar thermal degradation behavior. When PU resins were used for gap-filling adhesion, using Desmodur L as the raw material with the NCO/ (OH+COOH) molar ratio of 1.5 had the best bonding strength after warm water and repetitive boiling water soaked. |

| 起訖頁 |

79-89 |

| 刊名 |

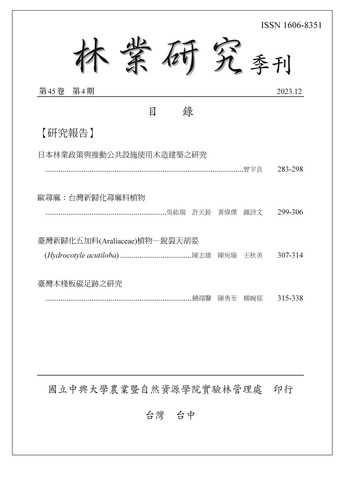

林業研究季刊 |

| 期數 |

201109 (33:3期) |

| 出版單位 |

國立中興大學農業暨自然資源學院實驗林管理處

|

| 該期刊-上一篇 |

無線射頻技術於森林樣區調查之效能評估 |

| |

|

新書閱讀

最新影音

優惠活動

|