|

本站僅提供期刊文獻檢索。 本站僅提供期刊文獻檢索。

【月旦知識庫】是否收錄該篇全文,敬請【登入】查詢為準。

最新【購點活動】 最新【購點活動】

|

| 篇名 |

台灣二葉松木材--塑膠複合材之理學機械性質

|

| 並列篇名 |

Physicomechanical Properties of Wood-Plastic Composites Made from Pinus taiwanensis |

| 作者 |

張懋如、吳東霖、洪克昌、陳載永、吳志鴻 |

| 中文摘要 |

本研究係探討台灣本土樹種台灣二葉松應用於木材塑膠複合材(Wood-plastic composites, WPC)時,其粒片尺寸、添加量及抽出成分對複合材理學及機械性質之影響。試驗結果顯示,以木材粒片尺寸6-16mesh及添加量為60%所製備之WPC,為兼具木質材料利用與機械性質之最適配比,而隨著木材粒片尺寸的減小及添加量的增加,其機械性質則有下降之現象。此外,當木材粒片/HDPE混合比(wt%)由20/80增加到80/20時,其抗彎彈性模數有先增後降的情形。另一方面,以醇苯萃取後之木材粒片所製備的WPC,其吸水厚度膨脹率雖較未萃取者高,但抗彎強度及木螺釘保持力則具有較佳表現,顯示台灣二葉松抽出成分會影響木材粒片與塑膠之界面性質,進而導致抗彎強度及木螺釘保持力呈現下降的現象。

This study investigated the effect of wood particle size, wood particle content and extractive on physicomechanical properties of wood-plastic composites (WPC) made from Pinus taiwanensis, a native free in Taiwan. Results demonstrated that the mechanical properties decreased with decreasing wood particle sizes or increasing wood particle contents. With the MOE, the modulus increased as the amount of wood particle increased up to 30% and then leveled off or remained constant up to 60%. Once the wood particle loading exceeded 60%, a significant decrease in the modulus was observed. Accordingly, for mechanical and economic considerations, the WPC with 60 wt% of wood particles (6-16 mesh) should be a suitable formulation. On the other hand, the thickness swelling of the WPC made from extracted wood particle was higher than that made from unextracted one, but the MOR and wood screw-holding strength of resulting WPC made from extracted wood particle were stronger than the other one. These results indicate that extractives of P. taiwanensis might have a negative effect on the interfacial properties between wood particles and polymeric matrix, and resulted in a significant decrease in MOR and wood screw-holding strength of WPC. |

| 英文摘要 |

This study investigated the effect of wood particle size, wood particle content and extractive on physicomechanical properties of wood-plastic composites (WPC) made from Pinus taiwanensis, a native free in Taiwan. Results demonstrated that the mechanical properties decreased with decreasing wood particle sizes or increasing wood particle contents. With the MOE, the modulus increased as the amount of wood particle increased up to 30% and then leveled off or remained constant up to 60%. Once the wood particle loading exceeded 60%, a significant decrease in the modulus was observed. Accordingly, for mechanical and economic considerations, the WPC with 60 wt% of wood particles (6-16 mesh) should be a suitable formulation. On the other hand, the thickness swelling of the WPC made from extracted wood particle was higher than that made from unextracted one, but the MOR and wood screw-holding strength of resulting WPC made from extracted wood particle were stronger than the other one. These results indicate that extractives of P. taiwanensis might have a negative effect on the interfacial properties between wood particles and polymeric matrix, and resulted in a significant decrease in MOR and wood screw-holding strength of WPC. |

| 起訖頁 |

65-74 |

| 刊名 |

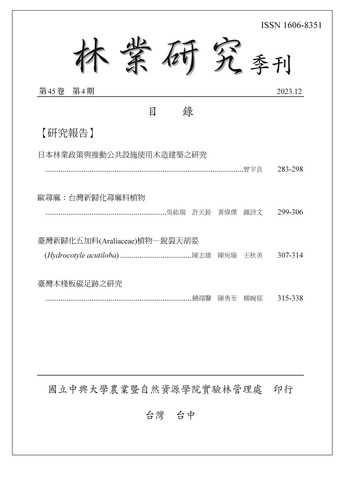

林業研究季刊 |

| 期數 |

200912 (31:4期) |

| 出版單位 |

國立中興大學農業暨自然資源學院實驗林管理處

|

| 該期刊-上一篇 |

國產主要竹種之竹炭與竹醋液之製造 |

| 該期刊-下一篇 |

材料尺寸對木質材料慢速熱解產物基本性質之影響 |

| |

|

新書閱讀

最新影音

優惠活動

|