|

本站僅提供期刊文獻檢索。 本站僅提供期刊文獻檢索。

【月旦知識庫】是否收錄該篇全文,敬請【登入】查詢為準。

最新【購點活動】 最新【購點活動】

|

| 篇名 |

AA-NC Semi-IPNs木器塗料——酸硬化胺基醇酸樹脂之合成與特性

|

| 並列篇名 |

AA-NC Semi-IPNs Wood Coatings—Synthesis and Characters of Acid Curing Amino-Alkyd Resin |

| 作者 |

盧崑宗 (Kun-Tsung Lu)、劉正字、林士棉 |

| 中文摘要 |

本試驗係探討大豆油變性醇酸樹脂(Alkyd)及胺基樹脂之合成特性,及分析常溫酸硬化型胺基醇酸樹脂(AA)中,不同胺基樹脂與醇酸樹脂比例對樹脂及塗膜性質之影響,以作為將AA與硝化纖維素(NC)合成半互穿聚合體網狀結構物(Semi-IPNs)之木器塗料時,選擇胺基醇酸樹脂之依據。試驗結果得知,油變性醇酸樹脂之反應率及平均聚合度均以短油型者>中油型者>長油型者。油溶性胺基樹脂之固形分及黏度均為三聚氰胺樹脂(MF)>尿素樹脂(UF),甲醛之釋出量則以UF> MF。又不同MF/UF 比例之AA 樹脂中, 以MUA-25(即重量比為MF/UF/Alkyd=7.5/22.5/70 者)之乾燥時間最短,塗膜抗彎曲性及硬度為最佳,耐衝擊性及耐磨耗性亦優良,但塗膜拉伸強度及破壞伸長率亟待改善。常溫酸硬化型之UA-30(即UF/Alkyd=30/70者)其樹脂與塗膜性質最為優良與均衡,但UF 之甲醛釋出量較多,此2種AA 樹脂將選用作為製備AA-NC Semi-IPNs 木器塗料之組成分之一。

The synthesis and characters of acid curing amino-alkyd resins(AA) with various amino resin/soybean oil modified alkyd resin ratios were examined in this study for choosing the proper AA resins to manufacture AA-NC semi-IPNs wood coatings. The results showed that the extent of reaction(P) and average degree of polymerization(DP) of oil modified alkyd resin were the sequence of that short-oil, medium-oil, and long-oil. The solid content and viscosity of melamine formaldehyde resin (MF) were higher than those of urea formaldehyde resin (UF) while the released formaldehyde of UF was higher than that of MF. The comparison of the AA resins with various MF/UF ratios, the MUA-25, i.e. MF/UF/Alkyd=7.5/22.5/70 (by wt.%) had the shortest drying time and best bending resistance and hardness of film, also had good properties of impact resistance and abrasive resistance of film, However, the tensile strength and elongation at break of the film must be enhanced. In addition, the UA-30, i.e. UF/Alkyd=30/70(by wt.%) had an excellent performance and balance on the properties of resin and film, while the more released formaldehyde had to be reduced. On these ground both of the two AA resins will be chosen for manufacturing AA-NC semi-IPNs wood coatings in the future study and be expected to improve the shortcomings of AA resins as mentioned above. |

| 英文摘要 |

The synthesis and characters of acid curing amino-alkyd resins (AA)with various amino resin/soybean oil modified alkyd resin ratios were examined in this study for choosing the proper AA resins to manufacture AA-NC semi-IPNs wood coatings. The results showed that the extent of reaction (P)and average degree of polymerization(DP)of oil modified alkyd resin were the sequence of that short-oil, medium-oil, and long-oil. The solid content and viscosity of melamine formaldehyde resin (MF) were higher than those of urea formaldehyde resin (UF) while the released formaldehyde of UF was higher than that of MF. The comparison of the AA resins with various MF/UF ratios, the MUA-25, i.e. MF/UF/Alkyd=7.5/22.5/70 (by wt.%) had the shortest drying time and best bending resistance and hardness of film, also had good properties of impact resistance and abrasive resistance of film, However, the tensile strength and elongation at break of the film must be enhanced. In addition, the UA-30, i.e. UF/Alkyd=30/70(by wt.%)had an excellent performance and balance on the properties of resin and film, while the more released formaldehyde had to be reduced. On these ground both of the two AA resins will be chosen for manufacturing AA-NC semi-IPNs wood coatings in the future study and be expected to improve the shortcomings of AA resins as mentioned above. |

| 起訖頁 |

69-81 |

| 刊名 |

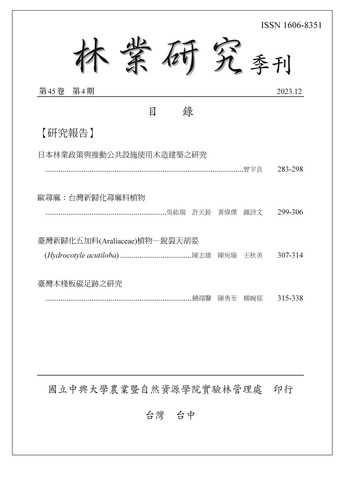

林業研究季刊 |

| 期數 |

200303 (25:1期) |

| 出版單位 |

國立中興大學農業暨自然資源學院實驗林管理處

|

| 該期刊-上一篇 |

台灣古蹟福州杉使用百年後之物理性質 |

| 該期刊-下一篇 |

大氣二氧化碳濃度與氮素影響森林生態系林木分布之初探——由林木生態生理學之觀點 |

| |

|

新書閱讀

最新影音

優惠活動

|