|

本站僅提供期刊文獻檢索。 本站僅提供期刊文獻檢索。

【月旦知識庫】是否收錄該篇全文,敬請【登入】查詢為準。

最新【購點活動】 最新【購點活動】

|

| 篇名 |

PE-NC semi-IPNs木器塗料(I)塗料之可使用時間及乾燥性

|

| 並列篇名 |

PE-NC semi-IPNs Wooden Coatings(I) Pot-life and Drying Character of Coatings |

| 作者 |

盧崑宗 (Kun-Tsung Lu)、李文昭、劉正字 |

| 中文摘要 |

本研究係將不飽和聚酯樹脂(PE)與硝化纖維素(NC)摻合而成PE-NC 半互穿聚合體網狀結構物(PE-NC semi-IPNs),並分析其作為木器塗料之可行性。其中PE 係由順丁烯二酸酐:鄰苯二甲酸酐:二乙二醇依莫耳比1:1:2.05 之條件反應而成,並添加30 % 之苯乙烯及不同比例催化劑(甲乙酮過氧化物)/ 促進劑(環烷酸鈷)/ 氧化防止劑(十二烷硫醇),調配成各種PE 塗料,另將PE 與NC 以不同重量比摻合製成PE-NC semi-IPNs,各調配塗料分別探討其可使用時間及乾燥性。試驗結果得知,各種配方之PE塗料,可使用時間以催化劑/ 促進劑/ 氧化防止劑=1.5 / 0.05 / 0.1(對樹脂重量之百分比)者最長,然僅達17 min,而PE-NC semi-IPNs 塗料則可大幅延長塗料之可使用時間。又各種配方之PE 塗料在常溫及空氣中均無法乾燥,而PE-NC semi-IPNs塗料在NC 含量在40 % 以上時,其塗膜可在常溫及空氣下乾燥,PE / NC=50 / 50 者塗膜乾燥時間可縮短至2.15 hr。

Unsaturated polyester resin (PE) was synthesized with maleic anhydride: phthalic anhydride: diethylene glycol=1:1:2.05 (molar ratio),and 30 % styrene (by wt.) would be added and mixed with catalyst (MEKPO) /accelerator (Co-Naph.) /oxidation inhibitor (dodecyl mercaptan) at various wt.% ratio to form PE coatings. Meanwhile, PE-NC semi-IPNs (Semi-interpenetrating polymer networks) were prepared by blending PE and NC (nitrocellulose) at various wt. % ratio for wooden coatings. The pot-life and drying character of PE and PE-NC semi-IPNs coatings were examined. The results revealed that PE coating at catalyst/ accelerator/ oxidation inhibitor=1.5/0.05/0.1 condition had the longest pot-life, but only 17 min. However, blending PE with NC, i.e. PE-NC semi-IPNs coatings, could prolong the pot-life of PE coatings significantly. All of PE coatings were unable to dry at room temperature and ambient atmosphere, but the films of PE-NC semi-IPNs coatings which NC content was above 40 % could be dried at the same environment, especially that of PE/NC=50/50 had the shortest drying time of 2.15 hr only. |

| 英文摘要 |

Unsaturated polyester resin (PE) was synthesized with maleic anhydride: phthalic anhydride: diethylene glycol=1:1:2.05 (molar ratio),and 30 % styrene (by wt.) would be added and mixed with catalyst (MEKPO) /accelerator (Co-Naph.) /oxidation inhibitor (dodecyl mercaptan) at various wt.% ratio to form PE coatings. Meanwhile, PE-NC semi-IPNs (Semi-interpenetrating polymer networks) were prepared by blending PE and NC (nitrocellulose) at various wt. % ratio for wooden coatings. The pot-life and drying character of PE and PE-NC semi-IPNs coatings were examined. The results revealed that PE coating at catalyst/ accelerator/ oxidation inhibitor=1.5/0.05/0.1 condition had the longest pot-life, but only 17 min. However, blending PE with NC, i.e. PE-NC semi-IPNs coatings, could prolong the pot-life of PE coatings significantly. All of PE coatings were unable to dry at room temperature and ambient atmosphere, but the films of PE-NC semi-IPNs coatings which NC content was above 40 % could be dried at the same environment, especially that of PE/NC=50/50 had the shortest drying time of 2.15 hr only. |

| 起訖頁 |

21-28 |

| 刊名 |

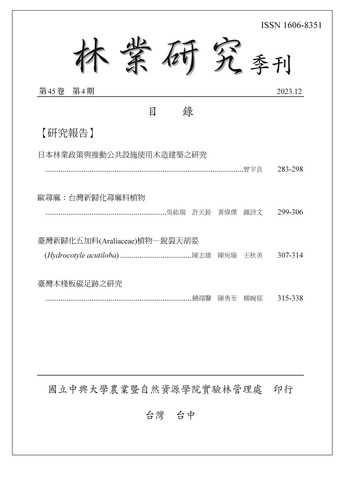

林業研究季刊 |

| 期數 |

200206 (24:2期) |

| 出版單位 |

國立中興大學農業暨自然資源學院實驗林管理處

|

| 該期刊-上一篇 |

社區居民對新化林場森林功能之認知與期望 |

| 該期刊-下一篇 |

彰化員林興賢書院木材利用及劣化調查 |

| |

|

新書閱讀

最新影音

優惠活動

|