|

本站僅提供期刊文獻檢索。 本站僅提供期刊文獻檢索。

【月旦知識庫】是否收錄該篇全文,敬請【登入】查詢為準。

最新【購點活動】 最新【購點活動】

|

| 篇名 |

含液化柳杉木材環氧樹脂及聚胺基甲酸酯樹脂所製備摻合樹脂之性質

|

| 並列篇名 |

The properties of blended resins prepared from epoxy resin and polyurethane resin containing liquefied Cryptomeria japonica wood |

| 作者 |

楊彝綱、李文昭 |

| 中文摘要 |

本研究將柳杉(Cryptomeria japonica)木材以酚/雙酚A及聚乙二醇/丙三醇為溶劑進行液化處理,所得液化木材(Liquefied wood;LW)與環氧氯丙烷(Epichlorohydrin)反應製備LW基質環氧樹脂(LW-based epoxy resin;LWER),與異氟爾酮二異氰酸酯(Isophorone diisocyanate;IPDI)反應製備含-OH、-NH2、-NCO等末端基之LW基質聚胺基甲酸酯樹脂(LW-based polyurethane resin;LWPU)。隨後將LWER樹脂及LWPU樹脂以重量比100/10混合調配摻合樹脂,並以示差熱掃描卡量儀(Differential scanning calorimeter;DSC)分析其反應特性。另添加三乙基四胺為架橋劑製作摻合樹脂成型物,並以傅利葉轉換紅外線光譜儀(Fourier transform infrared spectroscopy;FTIR)分析其化學結構,以萬能強度試驗機測定其彎曲性質,以熱重分析儀(Thermogravimetric analyzer;TGA)分析其熱抵抗性。DSC分析結果顯示LWER樹脂的環氧基可與PU樹脂的-OH、-NH2、-NCO等末端基發生反應。FTIR分析顯示硬化摻合樹脂結構中同時具備ER樹脂與PU樹脂之特性吸收峰。LWER/LWPU摻合樹脂所製造成型板呈現軟韌性質,其彎曲強度及彈性模數均較LWER成型板明顯降低。添加PU樹脂及LWPU樹脂可提高LWER樹脂受熱初期之熱安定性,然溫度250℃以上之熱抵抗性則降低。

In this study, wood of Cryptomeria japonica was liquefied with phenol/bisphenol A and polyethylene glycol/glycerol as solvents. The liquefied wood (LW) was reacted with epichlorohydrin to prepare LW-based epoxy resin (LWER) and reacted with isophorone diisocyanate (IPDI) to prepared LW based polyurethane resin (LWPU) that contains OH, NH2 and NCO-terminated groups. Then a blended resin was prepare by mixing LWER resin and LWPU resin at 100/10 weight ratio. The reactivity of the blended resin was analyzed with a differential scanning calorimeter (DSC). In addition, the blended resin was used to make molding boards after the addition of triethylenetetramine as a cross-linking agent. The chemical structure of the blended resin was measured with Fourier transform infrared spectroscopy (FTIR), the bending properties were analyzed using a universal strength testing machine, and the thermal resistance was analyzed with a thermogravimetric analyzer (TGA). The results of DSC analysis showed that epoxy groups of LWER resin could react with -OH, -NH2 and -NCO terminal groups of PU resins. FTIR analysis showed that the structure of cured blended resin had the characteristic absorption peaks of both ER resin and PU resin. Molding boards made with LWER/LWPU blended resin exhibited a soft-tough behavior, and their bending strength and elastic modulus were significantly lower than those of the LWER molding board. Adding PU resin and LWPU resin improved the thermal stability of LWER resin at the initial stage of heating, but decreased the thermal resistance at the temperature above 250℃. |

| 英文摘要 |

In this study, wood of Cryptomeria japonica was liquefied with phenol/bisphenol A and polyethylene glycol/glycerol as solvents. The liquefied wood (LW) was reacted with epichlorohydrin to prepare LW-based epoxy resin (LWER) and reacted with isophorone diisocyanate (IPDI) to prepared LW based polyurethane resin (LWPU) that contains OH, NH2 and NCO-terminated groups. Then a blended resin was prepare by mixing LWER resin and LWPU resin at 100/10 weight ratio. The reactivity of the blended resin was analyzed with a differential scanning calorimeter (DSC). In addition, the blended resin was used to make molding boards after the addition of triethylenetetramine as a cross-linking agent. The chemical structure of the blended resin was measured with Fourier transform infrared spectroscopy (FTIR), the bending properties were analyzed using a universal strength testing machine, and the thermal resistance was analyzed with a thermogravimetric analyzer (TGA). The results of DSC analysis showed that epoxy groups of LWER resin could react with -OH, -NH2 and -NCO terminal groups of PU resins. FTIR analysis showed that the structure of cured blended resin had the characteristic absorption peaks of both ER resin and PU resin. Molding boards made with LWER/LWPU blended resin exhibited a soft-tough behavior, and their bending strength and elastic modulus were significantly lower than those of the LWER molding board. Adding PU resin and LWPU resin improved the thermal stability of LWER resin at the initial stage of heating, but decreased the thermal resistance at the temperature above 250℃. |

| 起訖頁 |

81-92 |

| 刊名 |

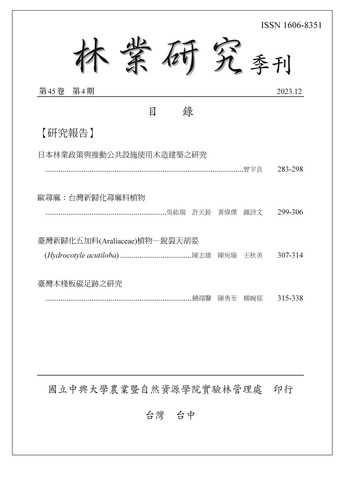

林業研究季刊 |

| 期數 |

201806 (40:2期) |

| 出版單位 |

國立中興大學農業暨自然資源學院實驗林管理處

|

| 該期刊-下一篇 |

台灣茶油產業新聞報導之內容分析 |

| |

|

新書閱讀

最新影音

優惠活動

|